Topnano can provide many kinds of nano-grade metal coating film OEM service by sputtering process according to customers' needs.

Roll-to-Roll Sputtering is a process used for large-area thin film deposition, commonly applied in the manufacturing of flexible electronic devices and thin-film capacitors.The core of this process involves depositing thin film materials onto a continuously moving substrate (such as polymer film, metal foil) using sputtering technology.

In addition, the quality of sputtered thin films is superior to evaporation technology in some aspects, such as adhesion and corrosion resistance.

* The thickness of the metal coating is only nanometer (max:150 nm).

*Only Cu plating can support Single-sided up to 18um thickness.

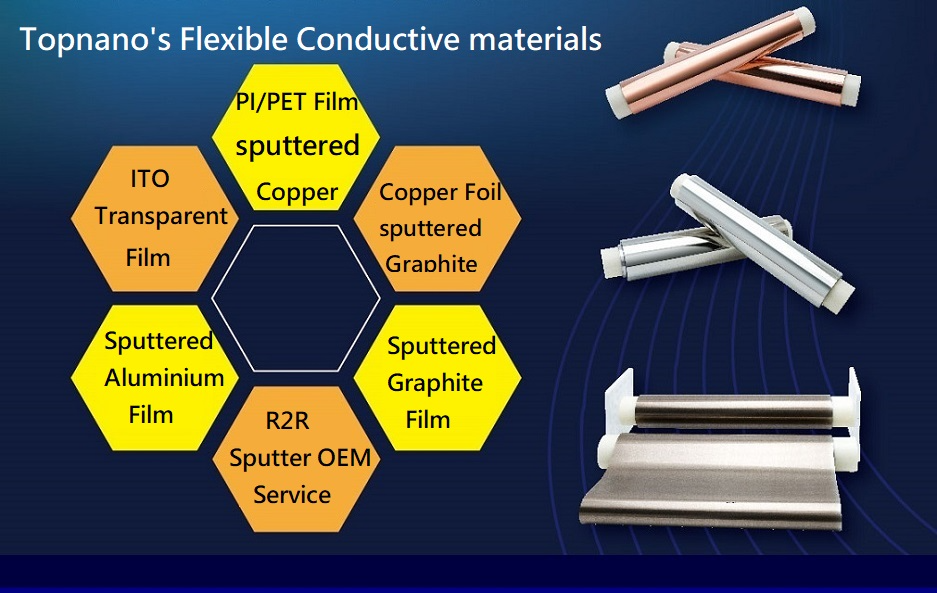

According to the type of material, we can provide two kinds of Sputtering service.

The metal/alloy is deposited on the polymer substrate (e.g. PI Film /PET Film) from metal target.

Examples of products: 2L-FCCL, ITO transparent conductive film.

(*Copper plating can supply up to 18um single side)

Metal foil (e.g. Cu Foil) is used as a substrate and other metals/alloys are sputtered on top to make electronic materials.

Product example: Copper foil sputtered Graphite Thermal film.

Customer product development/mass production case:

1. Assist Japanese companies in developing thermoelectric materials

2. Assist Japanese companies in developing new conductive film materials

3. Mass produce PET Film with copper-plated film for LED transparent displays for China customers

4. Assist Israeli customers in developing composite metal foil functional materials

5. Assist Taiwanese customers in developing functional materials

6. Improve the uniformity of the metal layer of customers' conductive materials with roll-to-roll process

When selecting roll-to-roll sputtering conductive film, R&D personnel will evaluate the differences between aluminum (Al), copper (Cu), ITO (Indium Tin Oxide), and graphite based on product requirements, cost, conductivity, transparency, adhesion, durability, etc.

The following is a comparison of various coating materials:

| Coating Material | Electrical Conductivity | Transparency | Flexibility | Oxidation Resistance | Typical Applications |

|---|---|---|---|---|---|

| Aluminum (Al) | Medium | None | Medium | Poor | Packaging films, EMI reflection |

| Copper (Cu) | High | None | High | Poor (requires protection) | EMI shielding, FPC circuits |

| ITO | Medium–High | High | Poor | Medium | Touch panels, transparent electrodes |

| Graphite | High | None | High | Excellent | Thermal dissipation, flexible electrodes |

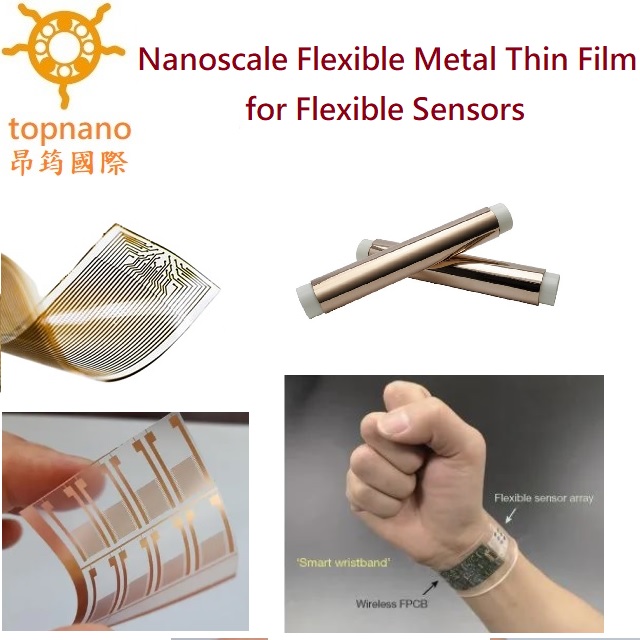

*Flexible sensors

For product inquiry / business collaboration, please contact us.

TOP Nanometal Corporation

Tel:+886-2-2298-3539 ext 8899

Fax:+886-2-2299-1200

Mail:joe_lin@topnano.com.tw

URL: www.topnano.com.tw/en-index.php

Address: 4F., No.13, Wuquan 7th Rd., Wugu Dist., New Taipei City 248, Taiwan (R.O.C.) (Headquarter)

Payment Terms: TT

Taiwantrade.com and iDealEZ.com uses analytical cookies and other tracking technologies to offer you the best possible user experience. By using our website, you acknowledge and agree to our cookie policy.

For more information on cookies or changing your cookies settings, read Taiwantrade & iDealEZ’s Privacy Policy.